“Good design is good business” - We know packaging design!

Visual impression is often the crucial factor for consumers when buying a product.

In our own design studio our passionate designers and skilled operators take your ideas and shape them into clear and concise concepts taking them all the way through the creative, photographic, artwork and repro stages.

Our design studio team will dress your products so the consumer cannot resist buying them.

Artwork & Repro

As you would expect, to deliver quality printing plates and sleeves we need to be experts in all aspects of artwork creation, repro and colour control for all print processes.

We have the capability to leverage as much automation and control as the customer requires through the data captured in our Atom Millnet workflow system.

Automated, intelligent artwork creation is a key driver for our digital solutions empowering the print experience. Starting with automating repetitive low value tasks, removing the risk and effort of duplicating data entry, followed by standard repro tasks and text management.

Colour Management

Miller Graphics provide the perfect link between creative design and print, ensuring your expectations are realised each and every time your designs go to print, across all packaging material types and all print processes.

We offer integrated prepress solutions to brand owners, retailers and printers, across European and African regions.

Thanks to a dedicated team of print professionals and the use of state-of-the-art technology we guarantee measurable, predictable and consistent print results, improving your brand’s shelf impact.

High-Quality Samples

We can supply you with high-quality digitally printed mock-ups to test and present your new products to your customers, allowing you to get to market weeks before final production. Present your ideas to the highest standards of realism, print and test your design, experiment with colours, materials and finishes.

Visualise your concept in the earliest stage possible – looking just like the real thing!

Miller Graphics is a member of FTA.

Print tools

Excellent print results requires excellent printing tools. Our expertise in extended colour gamut printing, high-quality printing plates & sleeves are contributing highly to your great flexoprint results!

Plates & ITR Sleeves

Miller Graphics Group are one of Europe’s leading suppliers of flexo plates and sleeves. Our production sites have pioneered with HD developments which allow us to combine the very best in HD software with superior plate types and ITR sleeves.

Our extended colour gamut tool with fixed colour palettes and our advanced screening technologies on plates help our clients achieve outstanding printed results and generate considerable ink saving on top of that.

We listen to our customers and embrace all available and new plate and sleeve technologies to find the most effective solutions. Miller Graphics will always be at the forefront of innovation and development to the benefit of our clients.

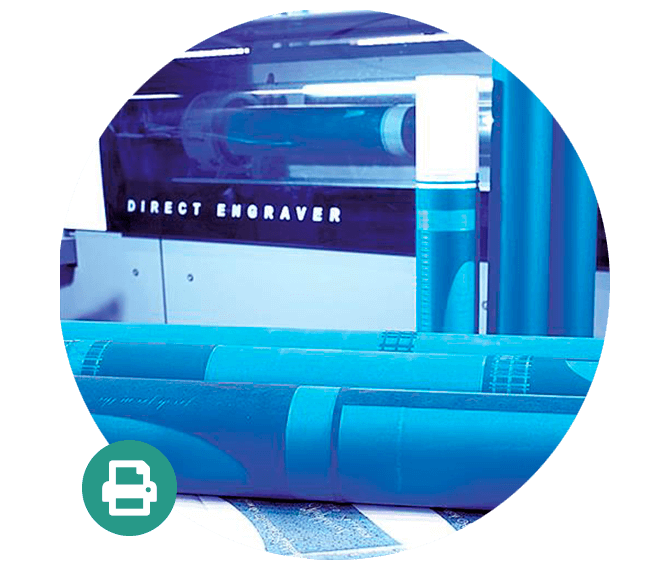

Direct Engraved Elastomer Sleeves

High-quality elastomer applied on fiber glass carriers are directly engraved with high definition lasers.

Our sleeves fit straight onto the press mandrels so there is no need for bridging tools.

The HD direct engraving process with the finest resolution and advanced surface screening on our durable and hard wearing sleeves offers the best ink transfer on all substrates.

MG Shift

Connecting brands to a broader colour space by using the extended colour gamut.

MG Shift supports the printing process by reducing complexity and making the print process more efficient and consistent. It gives access to around 90% of the Pantone colour space using a set of predefined process colours. Benefits are obvious and several: no time consuming stops to change colours and cleaning. Thus making it better for the environment and allowing much faster job changeover. This is an excellent way to help meeting the always shortening time to market and stringent deadlines.

Plate Mounting

Accurate pre-mounting of plates on Mylar for corrugated board printing on high-performance digital mounting equipment. Camera control offers the highest accuracy in register.

Quality control and risk management are secured by real time wet proofing on the mounting equipment.

The selected choice of plate, tape, foam and carrier, in combination with advanced colour management offers the best possible print results on corrugated board.